Custom Precision Motion Solutions

Delivering precision motion solutions for OEMs across industries—from medical devices to industrial automation.

Customization to Meet Your Unique Needs

At DINGS' Motion USA, we specialize in providing custom-engineered solutions for a wide range of motion control challenges. Whether you need precision, power, or a unique design to fit your specific application, our team of expert engineers works closely with you to develop tailored solutions that meet and exceed your performance requirements. From initial concept to final product, we partner with OEMs across diverse industries to bring innovative, reliable, and efficient motion control products to life.

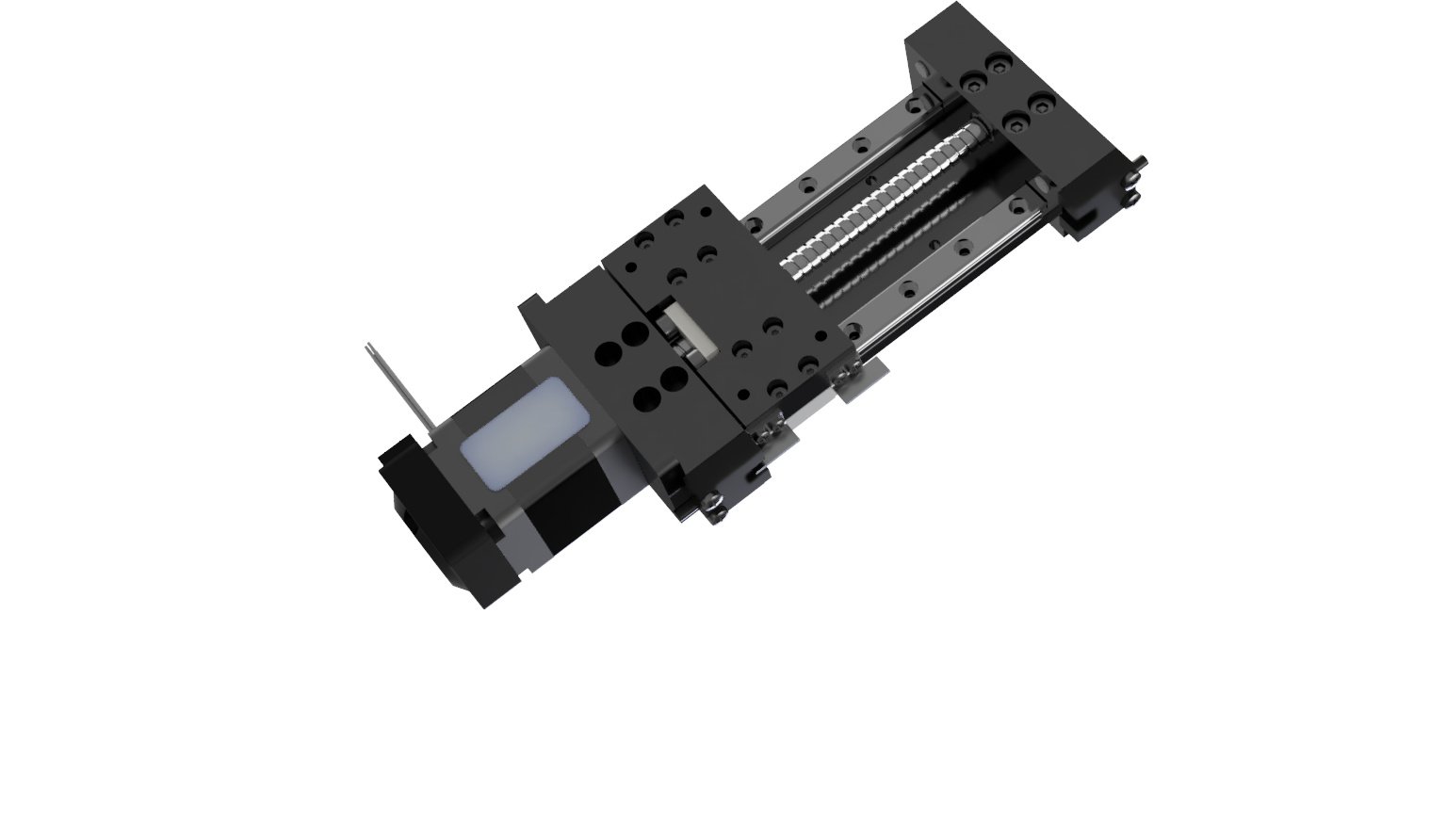

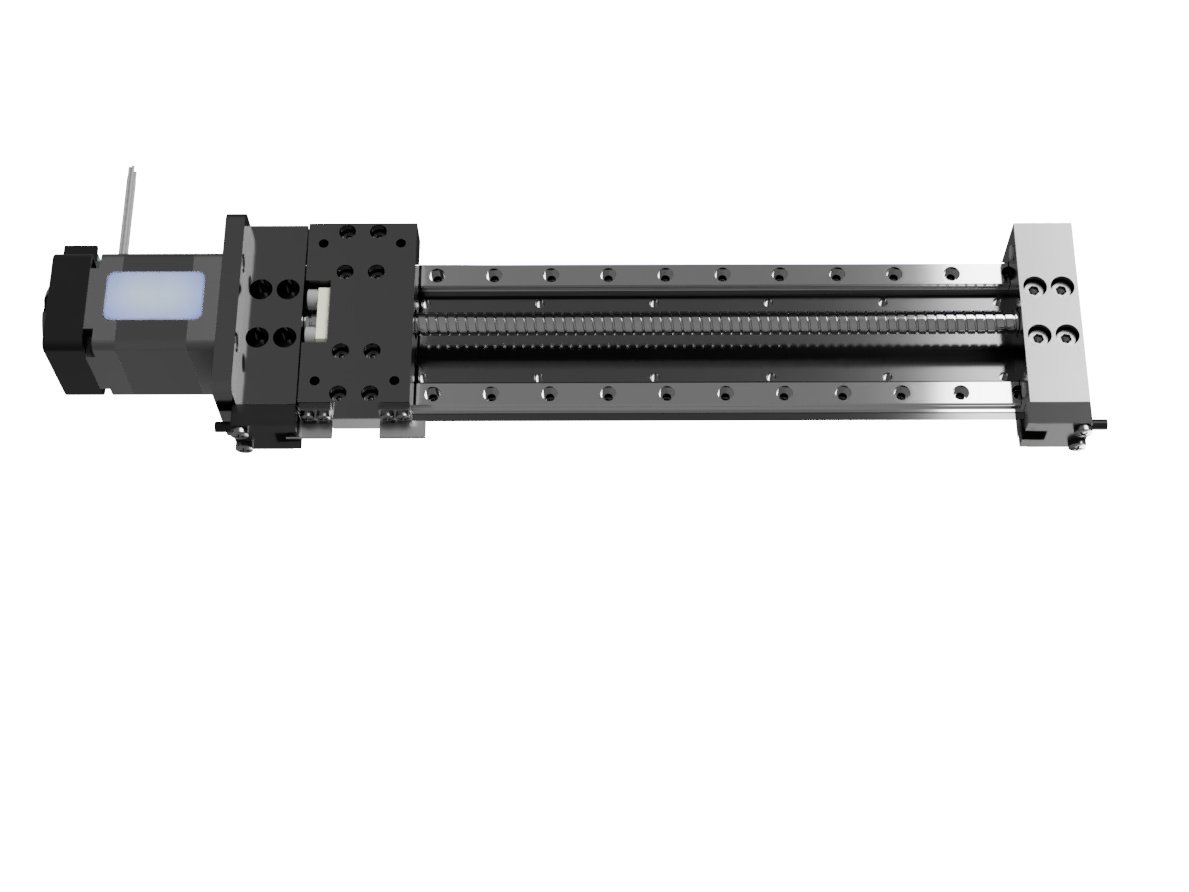

Custom Linear Actuators: Designed to deliver smooth and precise motion, our linear actuators can be tailored in NEMA size, stroke length, screw lead, electrical specifications, and more to fit the exact needs of your application. This includes hybrid stepper linear actuators, IP54 linear actuators, stepper ball screw linear actuators, can stack linear actuators, and more.

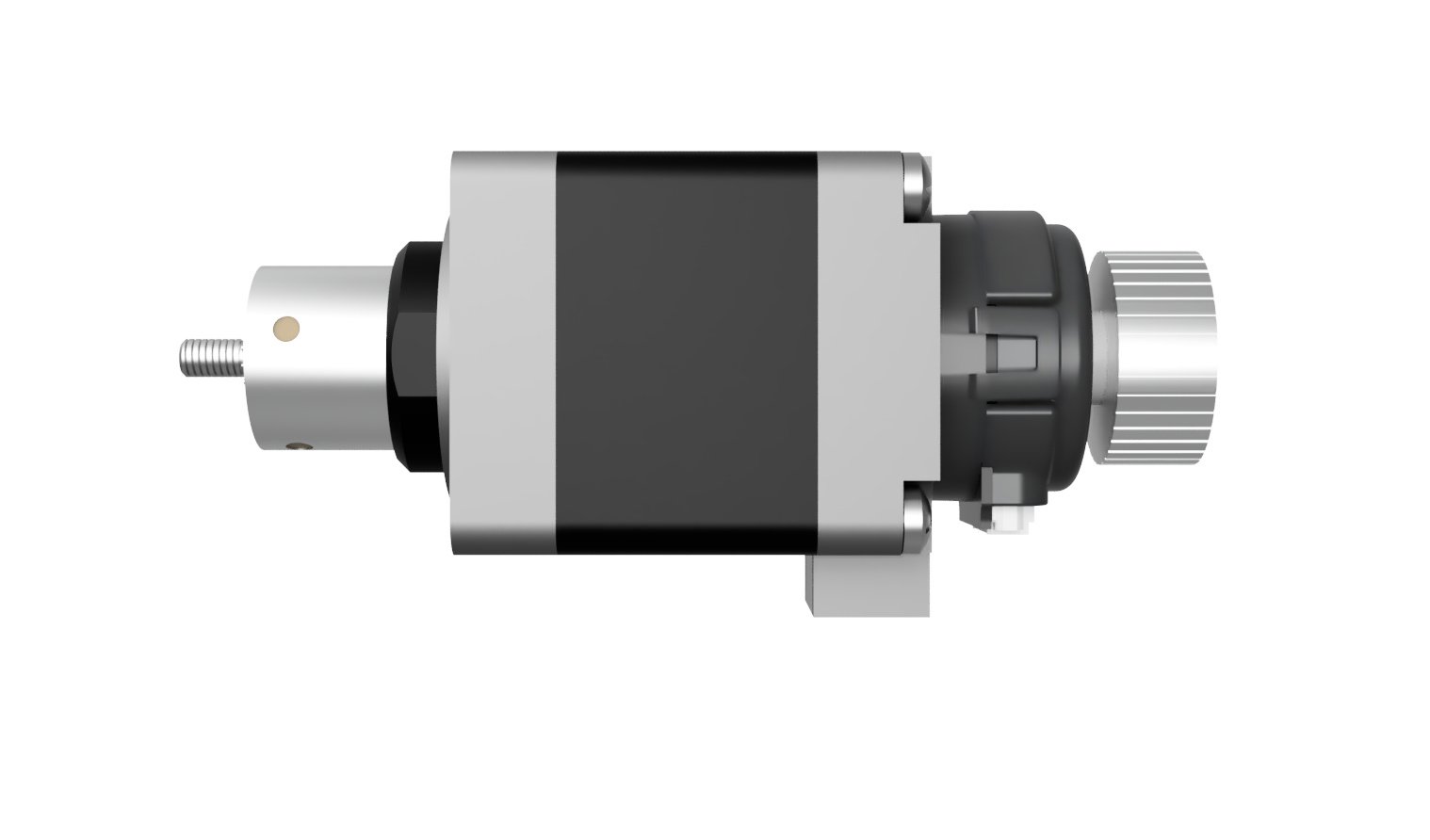

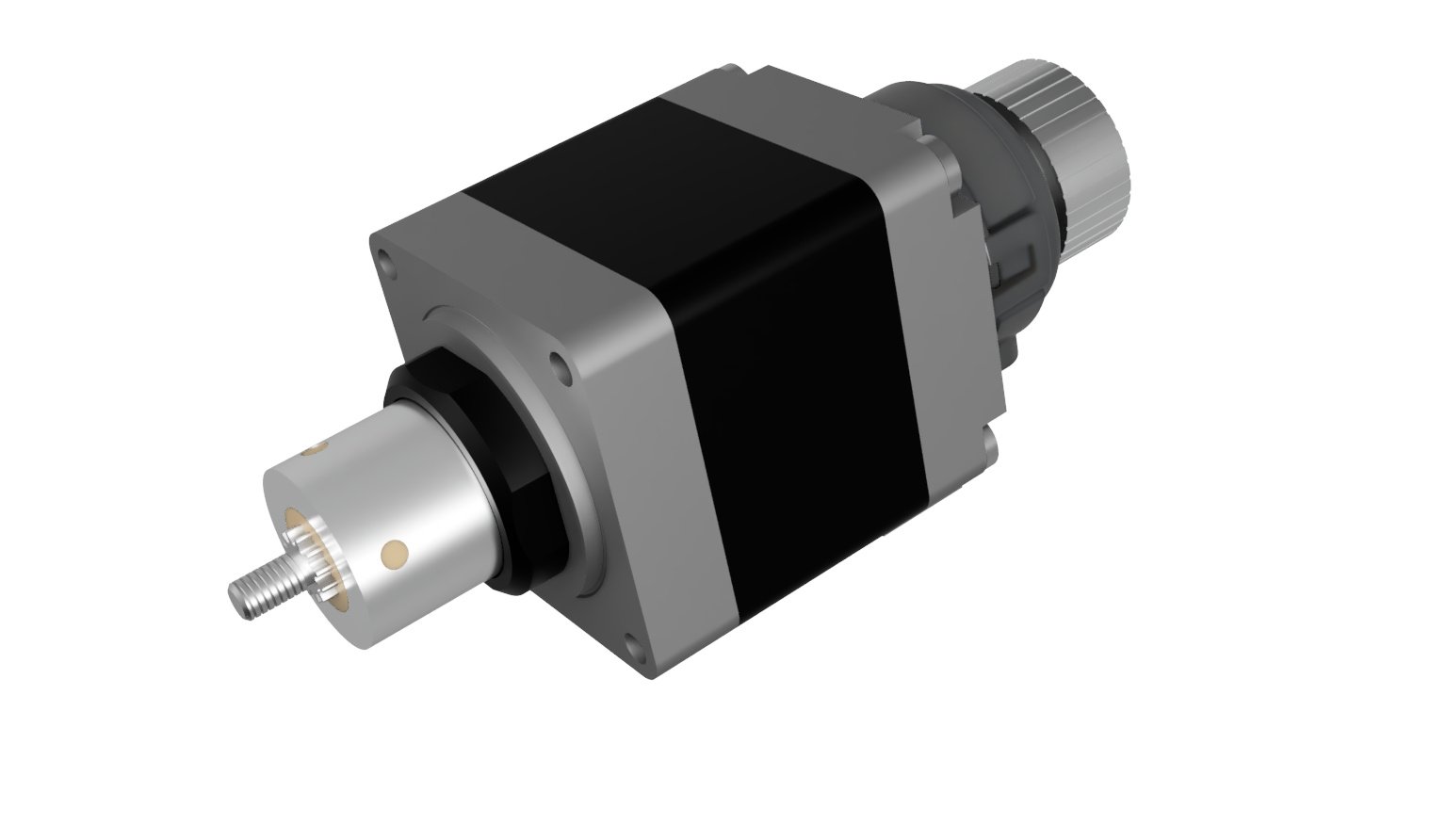

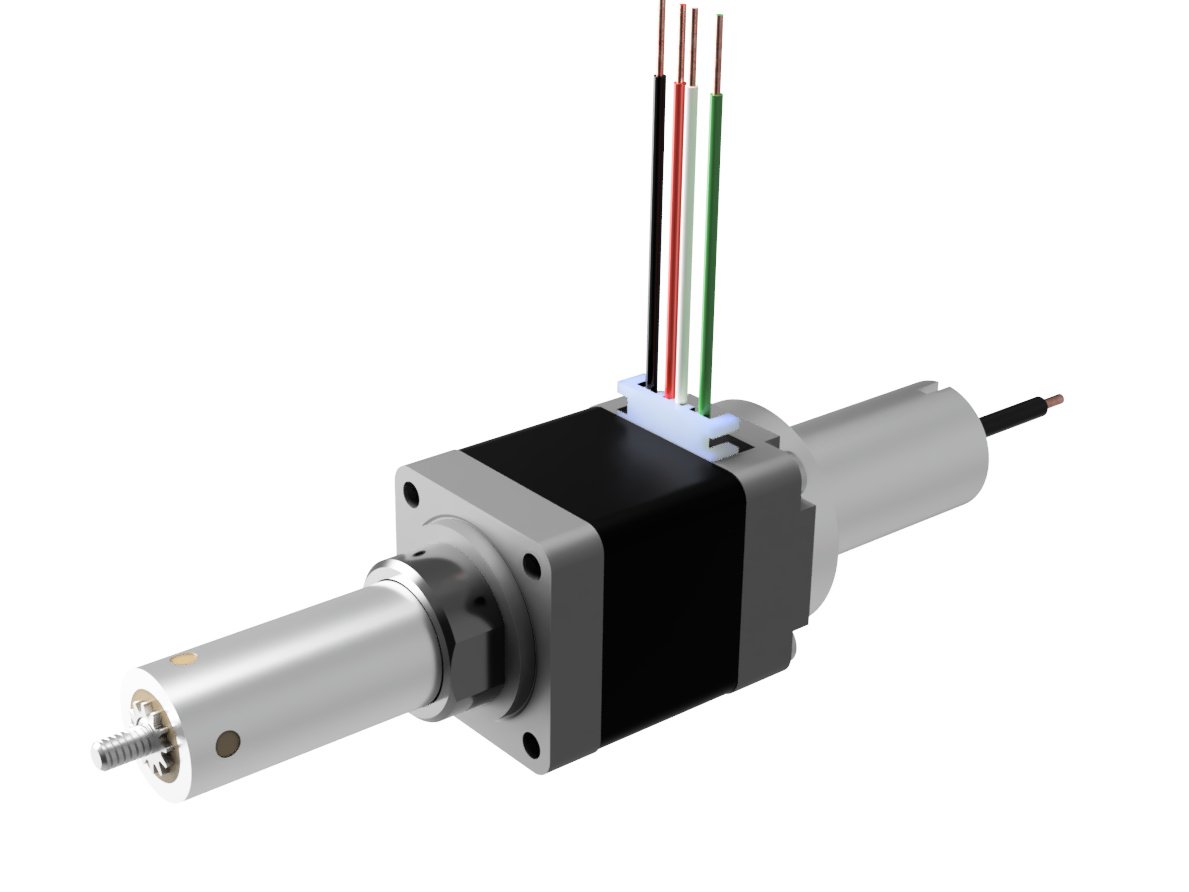

Custom Rotary Motors: With a focus on precision and control, our Stepper, Brushed, Brushless and Slotless Rotary Motors can be modified for torque, step angle, drive configuration, and more to meet your project’s unique specifications.

Check out some of the custom solutions we’ve created recently.

Custom Solutions

-

We customize Stepper Linear Actuators, PM Stepper Linear Actuators, Slide Actuators, and Voice Coil Motors. Customizations may include: NEMA size, stack size,stroke length, shaft configurations, motor types (stepper or BLDC), end machining, coatings, cabling / connectors, lubrication on lead screw, voltage / current ratings, windings, insulation class, speed, IP ratings, force / torque, and more. We also have clean room capabilities.

-

We customize rotary stepper motors, brushless DC motors, brushed DC motors, and servo rotary actuators. Customizations may include: multiple mounting configurations, windings, shaft configurations, encoders, gearboxes, dampers, cabling / connectors, bearings, lubricants, end machining, insulation class, voltage / current ratings, NEMA size, length, step angles and more. We also have clean room capabilities.

-

We can customize any of our screw & nut assemblies, robotic grippers, integrated motion systems, and drivers & controllers.

Industries Served

Biomedical & Healthcare

Laboratory Automation

3D Printing

Mobile Devices

Displays

Packaging

Factory Automation

Robotics

Fluid Control

Semiconductor

The Customization Process

-

Reach out to discuss your project and motion control requirements with our skilled engineers. We're here to help with custom solutions.

-

If confidentiality is required, we’ll sign an NDA to protect your information. Further back-and-forth may occur to refine specifications.

-

We’ll review your specs together to ensure we understand your needs, from performance details to application requirements.

-

We’ll provide a quote for samples and production quantities, giving you a clear path to prototyping and manufacturing.

-

Once approved, samples are created for testing and evaluation to ensure the product meets your exact specifications.

-

We’ll work with you to validate the fit, form, and function of the product, refining the design as needed.

-

After validation, we’ll finalize drawings and move into production, delivering your custom-engineered solution and providing full support moving forward.

Innovative Solutions in Action: Real-World Results for Our Clients

Ready to create your custom motion solution?

Dings’ Motion USA

335 Cochrane Circle | Morgan Hill, CA | 95037

Email: sales@dingsmotionusa.com

Phone: 408-214-3955