Integrated Motion Systems

DINGS’ MOTION USA

Vector Series: Integrated Motion Systems

Features and Benefits

Lower installation cost and set-up time: Can usually be set up out-of-the-box with little engineering effort required

Improved reliability: Fewer parts to connect, and less cabling / wiring

Reduced development time: Quick and easy programming

Reduced machine size / footprint, cost, complexity: Can even eliminate external controllers like PLCs

Integrated Drivers & Controllers

NEMA 23 Integrated Driver/Controller

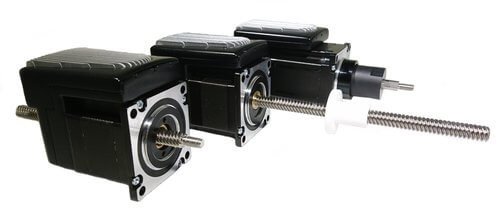

Form Factors (Left to Right): Non-Captive, External, Captive

Form Factors (Left to Right): Rotary Stepper Motor, Electric Cylinder

Features

HMI Interface

USB Programming Interface

Multifunction diagnostic LED

SnapTrack TM Programming Software

Secondary Encoder input for electronic gearing OR camming

Distributed Motion for Multi-Axis Control (Master and Slave)

Specifications

Input Voltage: 12-48 VDC

Variable Control Modes: Rated Torque Control, Linear Force Control

Current: 4 Amps/Phase Peak

Control: Dynamic Closed Loop or Open Loop

Programmable I/O's: 3 Digital Inputs (5V-24V), 3 Digital Outputs (5V-24V), 1 16-Bit Analog Input

Microstep Resolution: Up to 256 μsteps/step

Communication: Serial RS485